|

A

specific method divided in 4 steps :

1 - Realization of a simple

mold or formwork

reproducing the shape and the style of the architectural stone element

that you want to reproduce, using traditional and cheap

materials like water-repellent woodboard and styrofoam.

2 - Realization of a mortar composed of an abundant natural limestone aggregate comming from a local quarry, some white cement, some natural lime, and a natural dye oxide. 3 - Pouring and mold removing, by following a relatively precise timing, determined by the desired result. 4 - Juste after removing, application of a finishing surface work like the one practiced by stoneworkers, but faster and less tiring, to retrieve the typical aspect of the old carved limestone. |

Homemade wooden mold |

The

force and the tools of the concept :

|

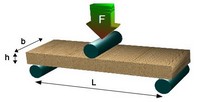

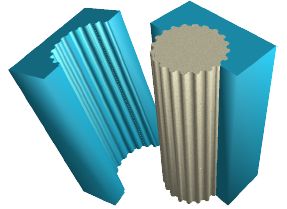

Reconstituted limestone pillar  On the wall formwork  Restored old stones  3 points flexion method |

|

|

|

|

More

about the Concept...

This

concept is very old since it seems to have been used

by the Egyptians,

testifies the polemic about the construction of the pyramids. It is

used

massively in cast stone industry and by some

stonemasons. In the hands of an handyman, it

enable to cast any architectural stone, out of

limestone, from the technique of pouring a concrete in molds

or formworks. The molds, very simple, are built out of wood

and water-repellent woodboard. They are reusable many times.

Plans and

examples of

realization are proposed for you on the site.

You

plan to restore your house or to build a new house. You are able to cut

a piece of wood, make a

hole with a drill, use a screw driver, make a formwork, mix

concrete

in a

small concrete-mixer and pour it in your formwork. So do not renounce

to give your house a little of the beauty and the nobility of

the stone because it is too expensive. Make your stones yourself. That

will not

be more expensive than the gray concrete and you will be

extremely

proud of the result…

The

concept is based on the original use of a very abundant

aggregate, dedicated until today to an other utilization, and

on the

use of very

traditional hydraulic binders in masonry. The recipe, the composition

and the proportioning of the basic mortar depend on the stone

application. All is detailed in the Molders' Manual.

The

stone obtained contains only materials comming from natural

mineral origin,

contrary to much of the market cast stones that contain

resins.

The

“limestone concrete” (fr -

béton calcaire) is used since the

beginning of the years 2000 in the realization of architectural

monuments with particularly beautiful esthetics.

To

make your stones, you must be able to find in a

store, a

deposit of materials or a limestone quarry in your

neighbourhood, fine crushed limestone aggregate, called

“fine

limestone 0-6 or 0-4” (fr - calcaire fin 0-6 ou 0-4).>> See the site du CRIT (Centre of Ressources and technical informations).

By

using a natural binder, a limestone aggregate comming

from a local quarry and

possibly using natural oxides powders, you are able to obtain cast

stones offering color, texture and natural properties very close to the

natural cut stones of

your old house. It is then easy to repair old stones

damaged by the time, or to supplement existing stones.

|

|

The

concept involve inescapable stages, well defined

in the time, that make possible to

obtain without effort a consistency and a surface quality of your

stone elements almost identical to those of natural calcareous stones.

Thank to the use of some traditional gestures

of the stone mason, the stone obtained is more realistic than the

majority of the cast stones available on the market of

buiding materials. These determining steps are very quite detailed in

the

guide.

The limestone obtained patinates naturally. It can be cut, brushed, be passed to French drag, be sandpapered, polished, glossed tinted and aged, exactly like natural stone. It's easy to obtain an ancient stone aspect. |

French drag finishing for cut stone aspect. |

Cost price

of the cast limestone : Less than 130€/m3

Cost

example of a terrace hollow pillar with mouldings, with a size of 30cm

x 30cm and 2.7m

height, including

:

approximately 65€/ton (1000kg) - 4 body elements 30cm x 30cm, 50 cm height - 1 capital 40cm x 40cm, 20 cm height ------------->

Master plan available on the site in the moulders space...

Cost of the

3 moulds (wood and agglomerated wood materials)

:

43€Cost of the limestone concrete by pillar (binder + limestone, 170 Litres) : 19€ Cost of the related materials used by pillar (5 inserts) : 7€ Total cost of only 1 pillar : 69€ Total cost by pillar for 4 pillars realized : 37€ / pillar

Average cost of an

equivalent pillar on the market : from

300€ to 800€ |

5

elements pillar with

mouldings,

made of limestone concrete, obtained with homemade molds. |

Rather

than to do it out of cement, why not to make

your lintel, your door sill, or even your arch or your porch, out of

limestone? Do

yourself your cladding stones, and even, simplify you the life by

casting your surrounding stones directly on your walls using

formworks…

Plans of molds are

proposed on the site. You can modify and adapt

them according to your need. With ideas and a few imagination, we

can make many things. You will quickly notice that the limestone

mortar is an extraordinary material, and so easy to

use…

|

Homemade wooden and styrofoam molds Molds plans available in the Moulders Workshop. |

| Home

- Concept

overview

- eBook

Guide - Limestone

Gallery - Moulds plans

- Moulders Workshop

- Partners - FAQ - Inspiration links - Site MAP - |

|

C

C

The

cut limestone moulders Manual

The

cut limestone moulders Manual Visit

the Gallery of the limestone molders

Visit

the Gallery of the limestone molders Molds

Plans downlod

Molds

Plans downlod